Hello,

I recently purchased this DS 7 E-Tense knowing it had an electrical issue. Moving into this vehicle from my 2014 CX-5 is an incredible step—it feels like changing planets! I’m genuinely impressed with the design and technology; it’s a fantastic-looking vehicle.

For me, this project is a hobby—a kind of gamble on a car that I can fix in my spare time! The good news is the car can drive, but there’s a significant warning indicating that electric drive is not possible.

So, I started investigating. The first thing I found was a blown 125A fuse in the trunk, which connects to the secondary battery. It looked like no one had been there before, which I took as a potentially good sign. I replaced this fuse and both 12V batteries (as I’d read that weak batteries can cause such errors). The fuse didn’t blow again, and the car’s condition is the same as it was before the electric drive issue. My theory is that it was a sort of “dead main battery” scenario, and on starting, a large current draw from the secondary battery might have blown the fuse.

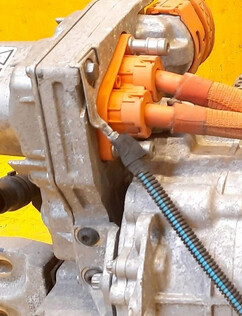

During this time, I was trying to use a standard OBD2 scanner for fault clearing, but it couldn’t do the job, so I ordered a PSA cable for DiagBox. I scanned the car, and there were about 25 faults, mainly attributed to a lack of power. I cleared what I could, and I’ve now narrowed the problem down to the RMCU_PHEV (Rear Motor Control Unit – Plug-in Hybrid Electric Vehicle).

There are hard faults for three temperature sensors indicating a short circuit to ground:

Fault Code Description

P11D9 Rear Electric Drive Temp Sensor Short Circuit to Earth

P11DB Rear Electric Drive Machine ECU Temp Sensor Short Circuit to Earth

P11DD Rear Electric Drive Inverter Temp Sensor Short Circuit to Earth

When reading standard parameters in DiagBox, I noticed that the voltage read by the module is around ∼10V, while the actual voltage is 12.5V.

This voltage discrepancy could be due to the shorted sensors causing a voltage drop, or perhaps a wiring harness issue. It’s possible that insulation degraded during the event that blew the 125A fuse. This seems more likely to me since three different temperature sensors in three different locations are showing the same short-to-ground fault.

It would be significantly easier if Stellantis wouldn’t restrict access to official repair manuals, as finding documentation is very difficult. I purchased Haynes Autofix, but it contains nothing important for this specific module or fault.

Does anyone know where I might source such documentation? Is it available through services like Autodata?

BR